Vacuum forming of plastics

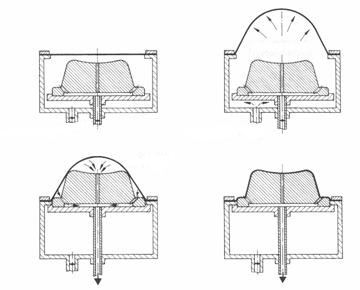

Vacuum forming technology uses the physical and mechanical properties of thermoplastic materials, which change the state of material into mouldable state when heated. The heated material is very malleable. It is stretched o nto a tools from which air is sucked out, resulting in a product that exactly copies the shape of the tool. The product is then cooled, so the plastic structure changes back to a solid state. This production method makes it possible to create everything from small parts to large structural units from sheets or foil.

Lower costs for tools production

Lower costs for tools production